Optimisation is one of the most commonly used term in corporate world, irrespective of functions. Normally optimisation refers to change in process, workflow, activities in order to improve efficiency and reduce cost. The most effective optimisation opportunities emerge from detailed process analysis, data-driven solutions, re-engineering, and automation, all aligned with the organisation’s long-term goals. Benefits of optimisation ranges from cost savings, better customer satisfaction, and sustained growth.

We can find numerous examples of failed optimisation projects across organisations, wherein common reason for the same ranges from lack of clear vision or measurable goals. Such optimisation projects lead to unfocused efforts or misalignment with business. In most of the optimisation projects, significant efforts focus on tangible factors like cost savings, revenue gains, or efficiency improvements, while intangible outcomes take a back seat. These intangible factors are not quantifiable but leads to sustained competitiveness for organisation. Such a scenario of over attention on short term tangible outcomes lead to situation of over optimisation.

Recent crisis of Indigo is classical example of over optimisation, wherein attention was to push low-cost model to its extreme. In aviation business aircrafts and pilots are back bone of network. Higher utilisation of these high-cost resources makes a good case of optimisation for airlines. Cost cutting in this case led to lean staffing, hiring freezes, pay freezes along, high resource utilisation, lower bench strength etc. This aggressive optimization of pilot utilization—stretching duties to limits like 70 hours monthly—backfired when new Flight Duty Time Limitations (FDTL) norms enforced stricter rest (48 hours weekly, night landings cut from 6 to 2).

Network-based logistics businesses operate within highly interconnected ecosystems where multi-level coordination, disciplined execution, and optimal asset utilisation are critical. A disruption at even a single node can cascade through the system, amplifying variability and triggering a bullwhip effect. These operating models typically rely on short lead times and stringent SOPs, which further heighten their sensitivity to imbalance. When over-optimisation is pursued without accounting for long-term implications and systemic risks, several common pitfalls emerge in logistics, including:

- Over-tight Routing: In a too tightly optimised network flexibility goes for a toss and small changes in demand, market conditions, or constraints can cause major disruptions

- Neck to neck optimised warehouse / transshipment space: Neck to neck optimised warehouse leaves no buffer for periodic / seasonal variation or change in demand supply scenario. Chocking of single node may lead to failure of major part of network.

- Excess of consolidation in transportation / Over-optimised Capacity Utilisation: Capacity optimisation is very common, but over optimisation may lead to delay and impace service quality. Which in longer term impacts customer loyalty as well.

- Zero-Buffer Plans OR No Bench Strength: Zero buffer in resources, or no bench strength is highly risky proposition. In normal scenario, one can pin point buffer as waste, but once disruption takes place, it acts as safety net.

- Multiple conflicting performance criteria: In logistics ecosystem there may be some conflicting KPI like cost/km, TAT, utilisation etc. For conflicting KPI aggressive optimisation leads to various issues.

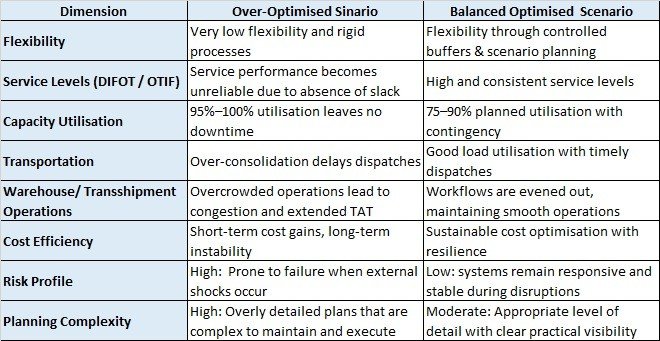

Over-optimisation leave no room for human error, variability, regulatory changes or unexpected situations. While balanced optimised scenario leaves space for responsiveness and resilience in overall operation, which is one of the essential components of logistics and supply chain.

So, balanced optimisation in logistics delivers stronger and more sustainable performance than over-optimisation because it blends efficiency with the flexibility needed to handle real-world variability. This approach not only controls costs but also improves reliability, making it far more effective for long-term logistics stability and customer satisfaction.